Stainless steel pipes and tubes are used in a variety of industries due to their durability and corrosion resistance, making them advantageous for most applications.

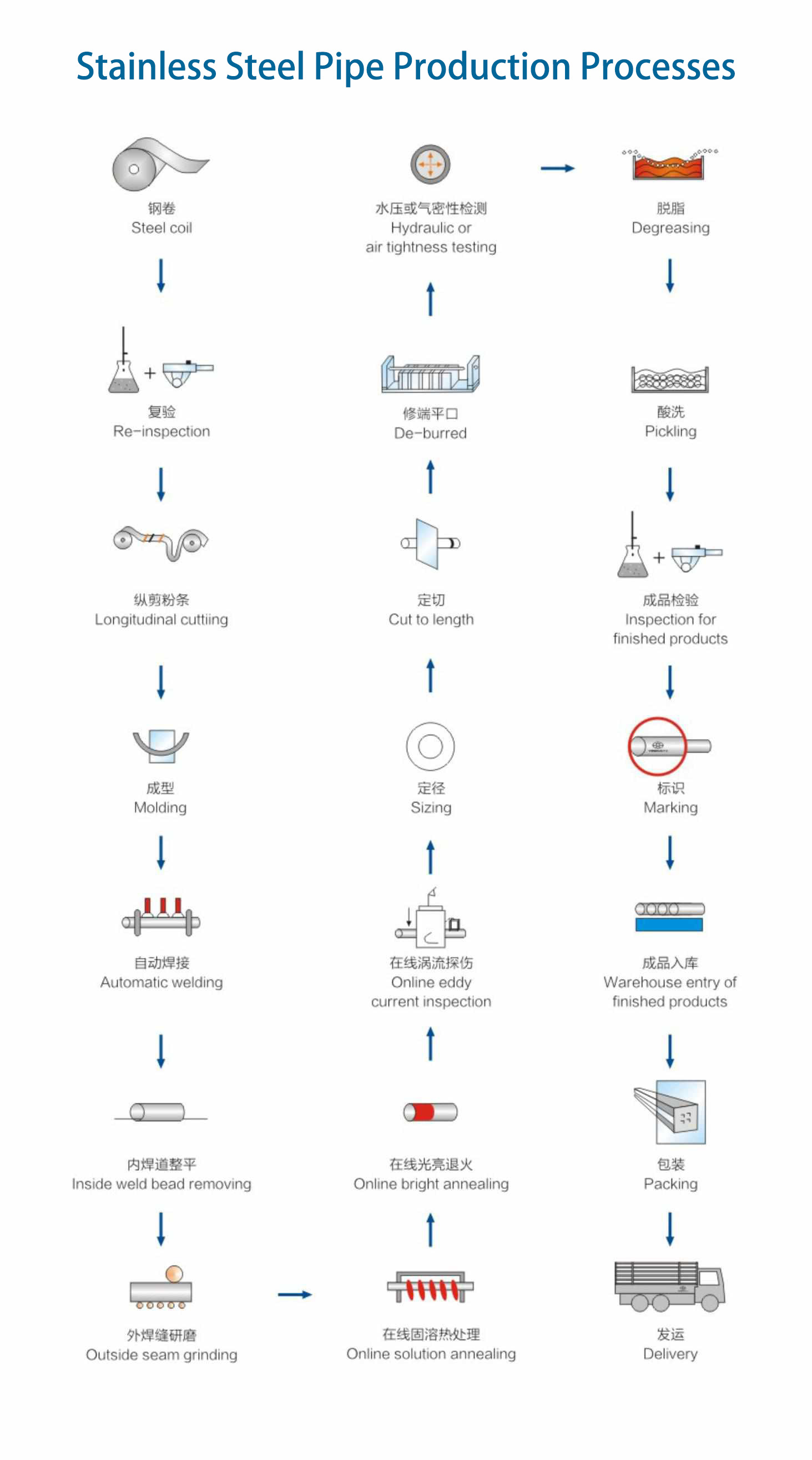

In this discussion, an overview of the stainless steel pipe manufacture processes will be provided. We will explore the various stages of the process, from the initial quality checks and welding, to the finishing stages such as cleaning, heat treatment, and marking.

By learning about the stainless steel pipe manufacture, one can gain an understanding of the various steps required for quality and durability.An understanding of the stainless steel pipe manufacture process is essential to ensure quality control.

Now let introduce the stainless steel pipe manufacture processes step by step

Stainless steel pipes are renowned for their exceptional durability and corrosion resistance. These qualities make them ideal for a wide range of applications, from industrial to residential use. stainless steel’s ability to withstand harsh environmental conditions, such as extreme temperatures and corrosive substances, ensures that pipes made from this stainless steel tube material maintain their integrity and functionality over time. This long-lasting performance not only reduces maintenance costs but also contributes to the overall efficiency and safety of systems where these pipes are utilized.

The first step of stainless steel pipe manufacture is to prepare the raw material. The manufacturer should select the right grade of the stainless steel coil according to the application of the pipe.

Then the stainless steel coils must be cut longitudinally to the required length.The coil is placed on a flat surface and cut using a circular saw or band saw. The cutting process ensures that the edges are neat and smooth, which is important for weld quality. It is important to ensure that the cutting is consistent and accurate.

Calendering is a process in which stainless steel coils are compressed to achieve the desired thickness. It apply pressure to stainless steel coils with roller to reduce the thickness and increase the length. This process is an important part of the stainless steel pipe and tube manufacturing process.

Quality inspection is also needed for raw material preparation. The quality inspector should test the chemical and mechanical properties of the stainless steel coil, and the thickness should be inspected before tube making.

The second step of stainless steel pipe manufacture is welding . Strips are fed to the tube mill and pass through rollers to achieve the desired size before a fitted welding machine is used to join the trim edges using TIG welding process.

The rolling and welding stage is essential to ensure the production of quality stainless steel pipes and tubes. The process involves a number of steps including quality checks, trimming of edges, welding, removal of scraps and weld beads, and forming of pipes and tubes. It is essential for welders to understand the process in order to properly produce quality products.

You may also like:

"Stainless Steel Tubing Welding 101: Tips for Success"

"The Difference of Stainless Steel Pipe TIG Welding and HF Welding"

After the rolling and welding stage, the next step in the stainless steel pipe manufacture is the cleaning and heating phase. Rolled stainless steel pipes are cut to required lengths and then cleaned to rid of dirt and debris.

Heat treatment follows to reduce stress caused by both welding and forming. This is done in a rolling hearth furnace. Pipes are then straightened and pickled to remove any scales from the surface.

Cold-drawing is a process used to obtain the desired size of pipes or tubes when it is not obtained directly from the mill. It involves coating the pipes or tubes with oxalic and soap solution as a lubricant before they are drawn over die plugs. This reduces the friction and helps to achieve the required size.

The cold-drawing process has several advantages, such as reducing friction, obtaining accurate size, and improving strength. However, it is also a time-consuming and costly process, with fewer options available. For these reasons, it is important for welders to understand the cold-drawing process and its limitations to make informed decisions during the stainless steel pipe manufacture process.

Stainless steel pipes are typically subjected to surface treatments to improve corrosion resistance and appearance. These treatments may include pickling, passivation, polishing, or coating with protective layers.

You may also like:

Once the pipes are manufactured and treated, they are cut to the desired lengths using methods such as sawing, shearing, or laser pipe cutting.

Testing and inspection are performed to ensure quality and accuracy of pipes and tubes. The pipes and tubes are tested for defects, accuracy, and strength. Dimension checks are done to ensure the pipes and tubes are of the desired stainless steel pipe dimensions and shape.

Non-destructive testing methods, such as x-ray examination, are used to detect any flaws in the structure. Eddy current testing is also a non-destructive testing technique used to detect and characterize surface and near-surface defects in stainless steel pipe. Mechanical property testing: flaring, flattening and flange testings will be after tube welding.

Computerized ink jet marking machines are used to mark the pipes and tubes with grade, size, heat number, and inspection stamp.

After the inspection andmarking stainless steel pipe will be packed in plastic bag , then several pipes will be packed in hollow plate or weaving bags.

Some client will require to packed them into wooden box or steel box. It will helps to ensure that the products are shipped safely and securely.

Stainless Steel Pipe Manufacture is an intricate one that involves a series of steps. From raw material preparation to cutting and sizing, testing and inspection, marking and packaging, every step is essential in ensuring that the pipes and tubes meet the industry standards of quality.

Through careful consideration of each step, welders, weld planners, and employers can ensure that the stainless steel pipes and tubes produced are of the highest quality. The result of this attention to detail is a stainless steel pipe and tube that is reliable, durable, and long-lasting.

With their superior strength and corrosion resistance, stainless steel pipes and tubes continue to be a key component of many industries.

Here's a video of stainless steel pipe manufacture process

Foshan Vinmay Stainless Steel Co., Ltd is a leading manufacturer specializing in high-quality stainless steel welded pipes. With a strong commitment to innovation and excellence, Vinmay has established itself as a trusted name in the stainless steel welded pipe industry. The company prides itself on providing customers with durable and corrosion-resistant stainless steel welded pipe products that meet the highest international stainless steel tube standards. Serving a global market, Vinmay’s expertise and dedication have made it a preferred partner for industries requiring reliable and robust stainless steel welded pipe solutions.

ASTM A554: This standard specification covers welded stainless steel mechanical tubing, often used in structural and ornamental applications. The tubing is made from flat-rolled steel by an automatic welding process without the addition of filler metal.

ASTM 270: ASTM A270 standard is primarily used for sanitary tubing in dairy, food, beverage, and other industries requiring high levels of sanitation. The tubing is polished and offers excellent cleanliness and corrosion resistance.

ASTM A249: This standard specification covers welded and seamless steel boiler, superheater, heat-exchanger, and condenser tubes. ASTM A249 pipes are known for their high-temperature resistance and are used in applications that demand high-pressure containment.

EN 10312: EN 10312 is a European standard that specifies requirements for welded stainless steel pipes intended for conveying water and other fluids. This standard ensures that the pipes meet stringent hygiene and mechanical property requirements.

Vinmay offers stainless steel pipes in various grades to suit different needs:

304/304L: Known for its excellent corrosion resistance and formability, 304 stainless steel is widely used in general piping and industrial applications. The 304L variant has a lower carbon content, which minimizes carbide precipitation during welding.

316/316L: The 316 grade contains molybdenum, enhancing its resistance to pitting and crevice corrosion, making it ideal for marine and chemical environments. The 316L variant, like 304L, has a lower carbon content for better weldability.

201: 201 stainless steel is an austenitic stainless steel with lower nickel content, making it more affordable while still offering good corrosion resistance and high tensile strength. It is commonly used in appliances, kitchen equipment, and automotive trim.

430: Grade 430 is a ferritic stainless steel known for its good corrosion resistance and formability, especially in mildly corrosive environments. It is magnetic and often used in applications like kitchen sinks, decorative trim, and automotive interiors.

Stainless steel pipes from Vinmay are used across a multitude of industries due to their versatility and reliability. Common applications include:

Vinmay’s dedication to quality and its comprehensive range of stainless steel pipes make it a trusted supplier in industries where performance, safety, and longevity are paramount.

Thank you for taking the time to go through all the information. If you have any additional questions, please don't hesitate to contact us. We are always ready to assist you.Also, don't miss the opportunity to explore our wide range of stainless steel pipe and order free samples today.